Hotline

+8615161118388

Working principle

The material enters the machine from the feed inlet. Under the action of the vibration force, the material is thrown along the horizontal fluidized bed and moves forward continuously. After the hot air passes through the fluidized bed and exchanges heat with the wet material, the wet air is discharged by the exhaust 1:3 after the dust is removed by the cyclone separator, and the dry material is discharged by the exhaust inlet.

Performance characteristics

◎ The vibration source is driven by a vibration motor, with stable operation, convenient maintenance, low noise and long service life.

◎ The fluidization is uniform, without dead space and blowing through, and can obtain uniform drying and cooling products.

◎ Good adjustability and wide application. The thickness of the material layer, the movement speed in the machine and the full amplitude change can realize stepless adjustment.

◎ It has little damage to the material surface and can be used for drying fragile materials. The irregular material particles will not affect the working effect.

◎ Fully enclosed structure is adopted to effectively prevent cross infection between materials and air, and the working environment is clean.

◎ High mechanical efficiency and thermal efficiency, good energy saving effect, 30-60% energy saving compared with general drying device.

Applicable materials

It is applicable to the drying and cooling of powder and granular materials in chemical, pharmaceutical, food, dehydrated vegetables, grain, mineral and other industries. Such as: citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, shredded radish, soybean meal, distiller's grains, seeds, slag, granulated sugar, etc.

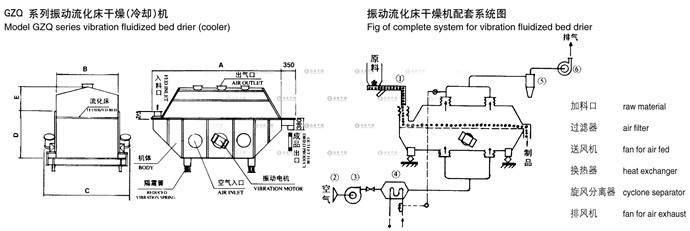

Structure diagram

| Measurement Model | A | B | C | D | E | F | Weight(kg) |

| ZLG3×0.30 | 3000 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| ZLG4.5×0.30 | 4500 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| ZLG4.5×0.45 | 4500 | 450 | 1550 | 950 | 430 | 1700 | 1670 |

| ZLG4.5×0.60 | 4500 | 600 | 1650 | 950 | 430 | 1700 | 1670 |

| ZLG6×0.45 | 6000 | 450 | 1650 | 950 | 430 | 1700 | 2100 |

| ZLG6×0.60 | 6000 | 600 | 1700 | 1000 | 500 | 1700 | 2410 |

| ZLG6×0.75 | 6000 | 750 | 1850 | 1000 | 600 | 1850 | 2840 |

| ZLG6×0.9 | 6000 | 900 | 2000 | 1000 | 600 | 1850 | 3160 |

| ZLG7.5×0.60 | 7500 | 600 | 1850 | 1000 | 600 | 1850 | 3200 |

| ZLG7.5×0.75 | 7500 | 750 | 2000 | 1000 | 600 | 1850 | 3600 |

| ZLG7.5×0.9 | 7500 | 900 | 2100 | 1000 | 600 | 1850 | 4140 |

| ZLG7.5×1.2 | 7500 | 1200 | 2500 | 1150 | 800 | 2050 | 5190 |

| Type | Fluidized bed area (m²) | Inlet air temperature (oC) | Air outlet temperature (oC) | Evaporation capacity (kg) | Vibration motor | |

| Model | Power Kw | |||||

| ZLG3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| ZLG4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| ZLG6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

| ZLG6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

| ZLG6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

| ZLG6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

| ZLG7.5×0.60 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

| ZLG7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

| ZLG7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0×2 |

| ZLG7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51-6 | 3.0×2 |

★ The above evaporation is the maximum evaporation.