Hotline

+8615161118388

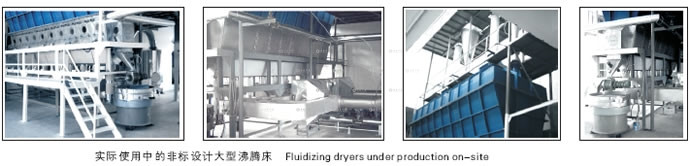

Product introduction

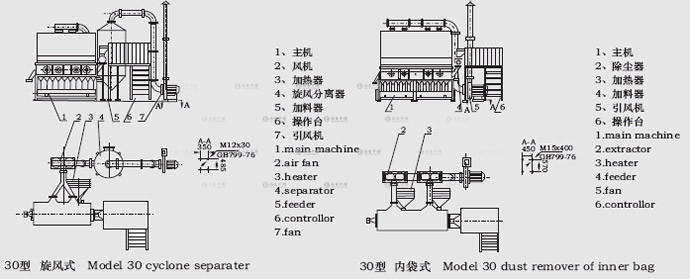

Boiling drying, also known as fluidized bed, is composed of air filter, heater, fluidized bed host, cyclone separator, bag filter, high-pressure centrifugal fan,  the composition of the operating platform, due to the different nature of the drying materials, when supporting the dust removal equipment, can be considered according to the needs, and can choose both cyclone separator and bag dust collector, or can choose one of them. Generally speaking, the cyclone separator is only needed for the drying of the granules and granular materials with large specific gravity, and the bag dust collector is required for the small granular and powdered materials with light specific gravity, and the pneumatic feeding device and belt conveyor are available for selection.

the composition of the operating platform, due to the different nature of the drying materials, when supporting the dust removal equipment, can be considered according to the needs, and can choose both cyclone separator and bag dust collector, or can choose one of them. Generally speaking, the cyclone separator is only needed for the drying of the granules and granular materials with large specific gravity, and the bag dust collector is required for the small granular and powdered materials with light specific gravity, and the pneumatic feeding device and belt conveyor are available for selection.

The granular solid materials are added into the fluidized bed dryer by the feeder, and the filtered clean air is heated and sent to the bottom of the fluidized bed by the blower to contact with the solid materials through the distribution plate, forming fluidization to achieve gas-solid heat and mass exchange. After drying, the material is discharged from the discharge outlet, and the waste gas is discharged from the top of the fluidized bed, and then discharged after the solid powder is recovered by the cyclone dust collector group and bag dust collector.

Steam, electric and hot blast furnaces can be matched (according to user requirements).

Working principle

The clean hot air is distributed into the bed through the valve plate, and the wet material entering from the feeder is boiled by the hot air. Due to the extensive contact between hot air and materials, the heat and mass transfer process is enhanced, so it can be dried in a short time. If the continuous type is used, the material enters from one end of the bed, and flows out from the other end of the bed automatically after boiling and drying for tens of seconds to several minutes. This equipment is generally operated under negative pressure.

Applicable materials

◎ Drying of pharmaceuticals, chemical raw materials, food, grain processing and feed. For example, drying and dehumidification of raw materials, tablet granules, traditional Chinese medicine granules, health food, beverage granules, corn germ, feed, plastic resin, citric acid and other powder materials. The particle size of applicable materials is generally 0.1~6mm, and the optimal particle size is 0.5~3mm.

Installation instructions

◎ All equipment shall be placed flat, fixed with foot screws, and all parts shall be well sealed.

◎ The fan can be placed outdoors or in the self-built silencing room. The plane layout can be adjusted according to the specific situation.

Structure diagram

| Specification and model Technical parameter | XF-0.25X1 | XF-0.25X2 | XF-0.25X3 | XF-0.25X6 | XF-0.3X2 | XF-0.3X4 | XF-0.3X6 | XF-0.3X8 | XF-0.3X10 | XF-0.4X4 | XF-0.4X6 |

| Bed area(m²) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 |

| Drying capacity(kg H₂O/h) | 10-15 | 20-25 | 30-45 | 52-75 | -30 | 42-60 | 63-90 | 84-120 | 105-150 | 56-80 | 84 |

| Fan power(kw) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 |

| Inlet air temperature(oC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| Material temperature(oC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

| Overall dimension(main engine)long × wide × high(m) | 1×0.6 | 2×0.6 | 4×0.6 | 6×0.6 | 2×0.70 | 4×0.7 | 6×0.7 | 8×0.7 | 10×0.7 | 4×1 | 6×1 |

| Area covered(m²) | 18×3.35 | 25×3.35 | 35×3.35 | 40×3.35 | 25×3.4 | 38×3.4 | 45×3.4 | 56×3.4 | 70×3.4 | 18×3.58 | 56×3.58 |

| Specification and model Technical parameter | XF-0.4X8 | XF-0.4X10 | XF-0.4X12 | XF-0.5X4 | XF-0.5X6 | XF-0.5X8 | XF-0.5X10 | XF-0.5X12 | XF-0.5X14 | XF-0.5X16 | XF-0.5X18 |

| Bed area(m²) | 3.2 | 4.0 | 4.8 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 |

| Drying capacity(kg H₂O/h) | 112-160 | 140-200 | 168-240 | 70-100 | 140-200 | 140-200 | 175-250 | 210-300 | 245-350 | 280-400 | 315-450 |

| Fan power(kw) | 44 | 66 | 66 | 30 | 66 | 66 | 90 | 90 | 150 | 150 | 165 |

| Inlet air temperature(oC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| Material temperature(oC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

Overall dimension (main engine) | 8×1 | 10×1 | 12×1.2 | 4×1.2 | 8×1.2 | 8×1.2 | 10×1.2 | 12×1.2 | 14×1.2 | 16×1.2 | 18×1.2 |

| Area covered(m²) | 74×3.58 | 82×3.58 | 96×4.1 | 50×4.1 | 70×4.1 | 82×4.1 | 100×4.1 | 140×4.1 | 180×4.1 | 225×4.1 | 268×4.1 |