Hotline

+8615161118388

Product use

This device is applicable to the recovery of dilute alcohol in pharmaceutical, food, light industry, chemical industry and other industries. It is also applicable to distillation of methanol and other solvents. According to the user's requirements, this device can distill about 30 ° diluted alcohol to 90~95 ° alcohol. If the precision of the finished product is very high, the reflux ratio can be increased, but the output will be reduced accordingly.

Equipment structural characteristics and technical performance

The device adopts high-efficiency ceramic corrugated packing. The distillation tower body is made of stainless steel, thus preventing the phenomenon of iron filings blocking the packing and extending the service life of the device. All equipment parts in contact with alcohol in this device, such as condenser, surge tank, cooling coil, etc., are made of stainless steel to ensure that the finished alcohol is not contaminated. The W-type distillation kettle uses detachable U-shaped heating pipe. During maintenance, the U-shaped heating pipe can be moved out of the kettle to facilitate cleaning of the outer wall of the heating pipe and the inner wall of the distillation kettle.

ZW type omits indirect heating distillation kettle. The condenser adopts the tubular heat exchanger, and the spiral plate heat exchanger can also be supplied according to the user's requirements. The cooler adopts the coil cooler, and the coil cooler is used, and the pressure stabilizing tank and the hydrometer are supplied.

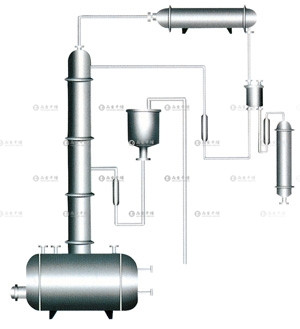

Device composition

Type W has five specifications, each of which includes the corresponding configured distillation tower, distillation kettle, condenser, cooler, stabilizer tank and hydrometer. W-200 and W-300 distillation towers are directly installed on the distillation kettle. W-400, W-500 and W-600 distillation towers and still are installed respectively.

ZW type has two specifications, ZW-200 and ZW-300, each of which includes the corresponding supporting preheater, distillation tower, condenser, cooler, stabilizer tank and hydrometer.

Other auxiliary equipment and instruments, such as metering tank, storage tank, delivery pump, rotameter, temperature indicating instrument, etc., are prepared by the user. Our factory can also process them separately or order them on behalf of the user.

◎ Feed concentration: 30%~80%

◎ Discharge concentration: 90% ~ 95%

◎ Reflux ratio: R=13 (depending on the concentration of incoming and outgoing materials)

◎ Residual liquid discharge alcohol concentration: W type ≤ 3%, ZW ≤ 1%

◎ Production capacity (kg/h):

| Model | Tower diameter (mm) | Production capacity of 30%~40% feed | Production capacity of 60%~80% feed | ||

| 90% | 95% | 90% | 95% | ||

| W-200 | Φ200 | 35 | 26 | 45 | 36 |

| W-300 | Φ300 | 80 | 61 | 100 | 80 |

| W-400 | Φ400 | 150 | 120 | 180 | 140 |

| W-500 | Φ500 | 230 | 185 | 275 | 220 |

| W-600 | Φ600 | 335 | 270 | 400 | 320 |

| ZW-200 | Φ200 | 95 | 60 | 110 | 80 |

| ZW-300 | Φ300 | 200 | 120 | 240 | 165 |