Hotline

+8615161118388

Working principle

◎ Heat energy (such as hot water, low pressure steam or heat transfer oil) is introduced into the closed interlayer, and the heat is transferred to the dried material through the inner shell.

◎ Under the power drive, the tank body rotates slowly, and the materials in the tank are continuously mixed, so as to strengthen the drying.

◎ The material is in a vacuum state, and the vapor pressure drops so that the water (solvent) on the surface of the material reaches the saturation state and evaporates, and is discharged and recycled by the vacuum pump in time. The water (solvent) inside the material continuously permeates, evaporates and discharges to the surface. The material can be dried in a short time.

Performance characteristics

◎ When the oil is heated, automatic constant temperature control is used to dry the biochemical products.

◎ With mineral raw materials, the temperature can be between 20 and 160°C.

◎ High thermal efficiency, more than 2 times higher than ordinary ovens.

◎ Indirect heating. The material will not be polluted and meets the requirements of "GMP". The equipment is easy to maintain and clean.

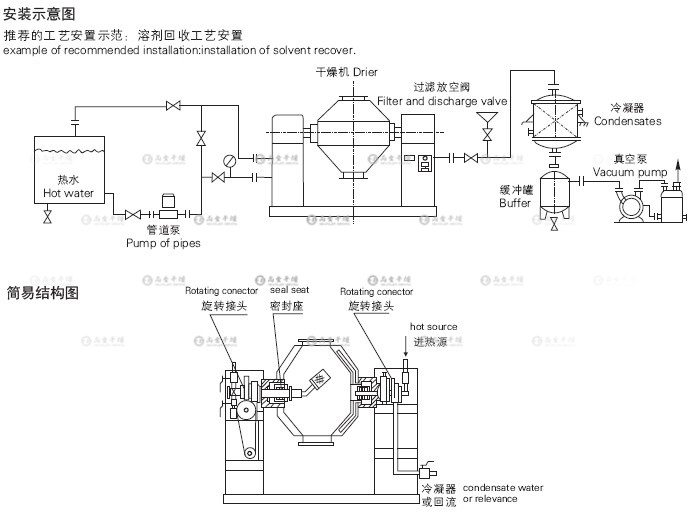

◎ Recommended process placement demonstration solvent recovery process placement.

Applicable materials

It is applicable to the concentration, mixing and drying of powder, granular and fiber in chemical, pharmaceutical, food and other industries, as well as materials that need to be dried at low temperature (such as biochemical products, etc.). It is also applicable to the drying of materials that are easy to oxidize, volatilize, heat sensitive, strongly irritating, toxic, and materials that are not allowed to destroy crystals.

| Specifications Name | SZG-100 | SZG-350 | SZG-500 | SZG-750 | SZG-1000 | SZG-1500 | SZG-2000 | SZG-3500 | SZG-4500 | SZG-5000 |

| Tank volume | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

| Loading volume (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 |

| Heating area (m²) | 1.16 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 11.2 | 13.1 | 14.1 |

| Speed (rpm) | 4 - 6 | |||||||||

| Motor power (kw) | 0.75 | 1.1 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 11 |

| Area covered Long×Wide(mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 |

| Swing height(mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 |

Design pressure in tank(MPa) | -0.1-0.15 | |||||||||

| Jacket design pressure (MPa) | ≤0.3 | |||||||||

| Working temperature (oC) | In tank≤85 Jacket≤140 | |||||||||

| When using condenser, vacuum pump, | 2X-15A | 2X-15A | 2X-30A | 2X-30A | 2X-70A | JZJX300-8 | JZJX300-4 | JZJX600-8 | JZJX600-4 | JZJX300-4 |

| Model, Power | 2KW | 2KW | 3KW | 3KW | 505KW | 7KW | 9.5KW | 11KW | 20.5KW | 22KW |

| When the condenser is not used, the vacuum pump, | SK-0.4 | SK-0.8 | SK-0.8 | SK-2.7B | SK-2.7B | SK-3 | SK-6 | SK-6 | SK-9 | SK-10 |

| Model, Power | 1.5KW | 2.2KW | 2.2KW | 4KW | 4KW | 5.5KW | 11KW | 11KW | 15KW | 18.5KW |

| Weight(kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 |

Note: For materials with large volume changes before and after drying, the loading coefficient can be appropriately increased or decreased.