Hotline

+8615161118388

Summary

RL granulator uses the melting point of materials lower than 250 ℃. According to the viscosity range of materials in the molten state, the molten liquid is evenly distributed on the steel belt moving at a uniform speed under the special distribution device. Under the cooling effect of the continuous spray device set under the steel belt, the materials are cooled, solidified and packaged in the process of transportation and transportation, so as to achieve the purpose of granulation molding.

the molten liquid is evenly distributed on the steel belt moving at a uniform speed under the special distribution device. Under the cooling effect of the continuous spray device set under the steel belt, the materials are cooled, solidified and packaged in the process of transportation and transportation, so as to achieve the purpose of granulation molding.

Performance characteristics

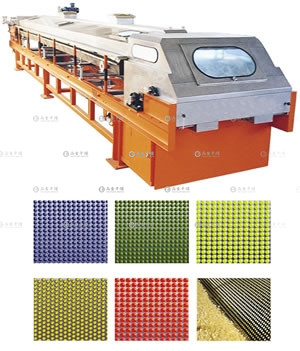

This product is a new type (melting) molding granulator. Thin steel strip heat transfer and atomization spray cooling are used to rapidly solidify the molten liquid, and a single rotating shell is used. Therefore, it is easy to maintain, with little wear and high productivity. Fast loading, unloading and replacement of products. In addition, the falling mold forming machine and the steel belt can run synchronously, thus producing uniform ingots at high speed, improving productivity and increasing production profits. It can eliminate dust, improve the environment and significantly expand the viscosity range. This product is an economic and reliable production process, which can be processed Φ 4-12mm particles, these products are very uniform, in the shape of hemisphere, strip and sheet, stable, no thermal stress and high purity and quality. Because the equipment is equipped with filter and plug removal device, the operation is more reliable.

Structure(1)

According to the melting point (freezing point) of the processed products, the temperature and viscosity of the materials and the cooling effect, the conveying speed and the rotating speed of the machine head are selected to avoid affecting the production capacity and granular quality.

The machine changes from liquid to solid granules, mainly through granulation die, continuous granulation by rotary steel belt, and shaping by spray water cooling.

Structure(2)

The machine is mainly composed of blanking die granulation molding head, cooling conveyor stainless steel belt and pulley, spray cooling system, transmission system, thermal insulation device, frame, scraper, etc. The blanking die granulating head is mainly composed of the head die sleeve and the head mandrel. The spray cooling system is mainly composed of nozzle, water tank, etc. The transmission system is mainly composed of speed regulating motor of reduction box (reducer).

Applicable materials

This product is applicable to all kinds of materials whose melting point (or softening point) is between 50 ℃ and 300 ℃, and materials with "supercooled crystallization" characteristics.

Technical requirement

Materials must be filtered and solid impurities must not enter the granulator head, otherwise the head will be worn or blocked, affecting the granulation quality.

The temperature control shall be determined according to the melting point temperature, and the temperature change of insulation shall not exceed ± 3 ℃. The cooling system shall be equipped with filter screen, and the temperature of cooling water is generally between 5 ℃ and 25 ℃ (low water temperature, fast molding, good granulation, high yield).

Summary

This product is a new type (melting) molding granulator. The working process changes from liquid to solid through transportation and cooling. Materials with melting point ranging from 50 ℃ to 300 ℃ can be granulated. No dust, improving the production environment; It has certain economic value (energy saving, packaging container economy), fast product replacement, beautiful granular products, uniform and nearly hemispherical granular, without thermal stress; Granular products are not only easy to package, transport and store, but also convenient for users to measure, mix or remelt, and can be produced continuously. From feeding to packaging, it reduces physical labor, has stepless speed regulation, adjustable flow, and convenient operation. It is widely used in petroleum, fine chemical and other industries. One machine can be used to make strips, cut pieces and flakes; Toxic materials can be sealed.

Model | RL60-A | RL60-B | RL60-C | RL60-D | RL120-A | RL120-B | RL120-C | RL120-D |

Effective heat transfer area(m²) | 2.6 | 3.6 | 4.6 | 5.3 | 7.3 | 9.3 | 10.8 | 16.6 |

Main/auxiliary motor power(kw) | 1.5/0.75 | 1.5/0.75 | 1.5/1.1 | 1.5/1.1 | 3/1.5 | 3/1.5 | 3/1.5 | 4/2.2 |

Overall dimension(mm) | 5600×1200 ×1800 | 7200×1200 ×1800 | 8800×1200 ×1800 | 10050×1200 ×1800 | 7200×1700 ×1800 | 8800×1700 ×1800 | 10050×1700 ×1800 | 14800×1700 ×1800 |

Productive power(kg/h) | 80-100 | 100-150 | 120-180 | 150-250 | 300-380 | 360-420 | 380-500 | 500-800 |

All up(kg) | 1360 | 1580 | 1880 | 2060 | 2380 | 2590 | 2830 | 4210 |