Hotline

+8615161118388

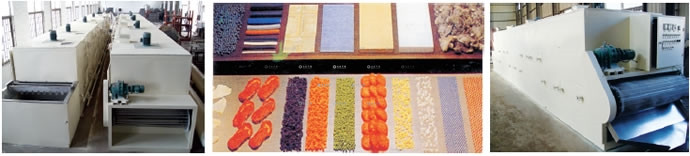

Product introduction

This machine is a through-flow continuous drying equipment, which is used for drying of sheet, strip and granular materials with good permeability, especially suitable for materials with high moisture content, such as dehydrated vegetables and traditional Chinese medicine slices, and the temperature is not allowed to be high; This series of dryers has the advantages of fast drying speed, high evaporation intensity and good product quality. For the paste material like dehydration filter cake, it can be dried after granulation or rod-shaped.

Working principle

The material is evenly laid on the mesh belt by the feeder. The mesh belt generally uses 12-60 mesh stainless steel mesh, which is dragged by the drive device to move in the dryer. The dryer is composed of several units, each of which has an independent circulation of hot air. Part of the tail gas is discharged by a special moisture exhaust fan. The exhaust gas is controlled by a regulating valve. The hot air passes through the mesh belt covered with materials from bottom to top or from top to bottom to complete the process of heat and mass transfer and take away the moisture of materials. The mesh belt moves slowly, the running speed can be adjusted freely according to the material temperature, and the dried finished products fall into the feeder continuously. The upper and lower circulation units can be flexibly equipped according to user needs, and the number of units can also be selected according to needs.

Performance characteristics

◎ It can adjust the air volume, heating temperature, material residence time and feeding speed to achieve good drying effect.

◎ The equipment configuration is flexible, and the mesh belt flushing system and material cooling system can be used.

◎ Most of the air is recycled to save energy.

◎ The unique air distribution device makes the hot air distribution more uniform and ensures the consistency of product quality.

◎ The heat source can be steam, heat transfer oil, electricity or coal (oil) hot blast stove.

Applicable materials

Dehydrated vegetables, pellet feed, monosodium glutamate, coconut, organic pigment, synthetic rubber, polypropylene fiber, medicine, medicinal materials, small wood products, plastic products, electronic non-device aging, curing, etc.

| Model | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-10 | DW-2-20 | |

| Number of units | 4 | 5 | 4 | 5 | 4 | 5 | 10 | |

| Tape width(m) | 1.2 | 1.6 | 2 | |||||

| Length of drying section(m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 | |

| Paving thickness(mm) | 10-80 | |||||||

| Service temperature(°C) | 50-140 | |||||||

| Steam pressure(MPa) | 0.2-0.8 | |||||||

| Steam consumption (kg/h) | 120-300 | 150-375 | 150-400 | 180-500 | 180-500 | 225-600 | 450-1200 | |

| Drying time (h) | 0.2-1.2 | 1.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.5-3 | |

| Drying strength kg水/h | 60-160 | 80-200 | 85-220 | 100-260 | 100-260 | 120-300 | 240-600 | |

| Total power of equipment (kw) | 11.4 | 13.6 | 14.6 | 18.7 | 19.7 | 24.5 | 51 | |

| Long(m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 | |

| Overall dimension | Wide(m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 |

| Tall(m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 | |

| All up kg | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 | |